A Visit to Brouwerij 3 Fonteinen

On a warm, gray Saturday morning in the beginning of August, I took the train a few stops from Brussels Central Station to Lot Station. I walked a few blocks and arrived at Lambik-o-Droom, Brouwerij 3 Fonteinen’s tasting room. Although it was cloudy outside, the tasting room was bright, with off-white walls, lightbulbs strung inside empty bombers, and tables made from old foeders. I paid €15 for a tour (Fridays and Saturdays at 10:30 AM only) and was escorted into their barrel room.

The tour started with a round of introductions. We were a worldly bunch with groups from Estonia, Sweden, Brazil, Germany, England, Australia, and the USA. Our tour guide, Senne Eylenbosch, poured us a round of young lambic from a traditional stoneware pitcher. It was light, citrusy, and tangy with a nice, smooth, effervescence. While we drank, Senne provided some historical information on 3F. Back in the 1880s, people still traveled by horse. The horses had to stop periodically to drink water, so the humans stopped frequently as well. While the horses drank water, the humans were drinking from 3 fountains: lambic, faro (sweetened lambic), and kriek (cherry lambic). Hence the name Drie Fonteinen (3 Fountains in Dutch).

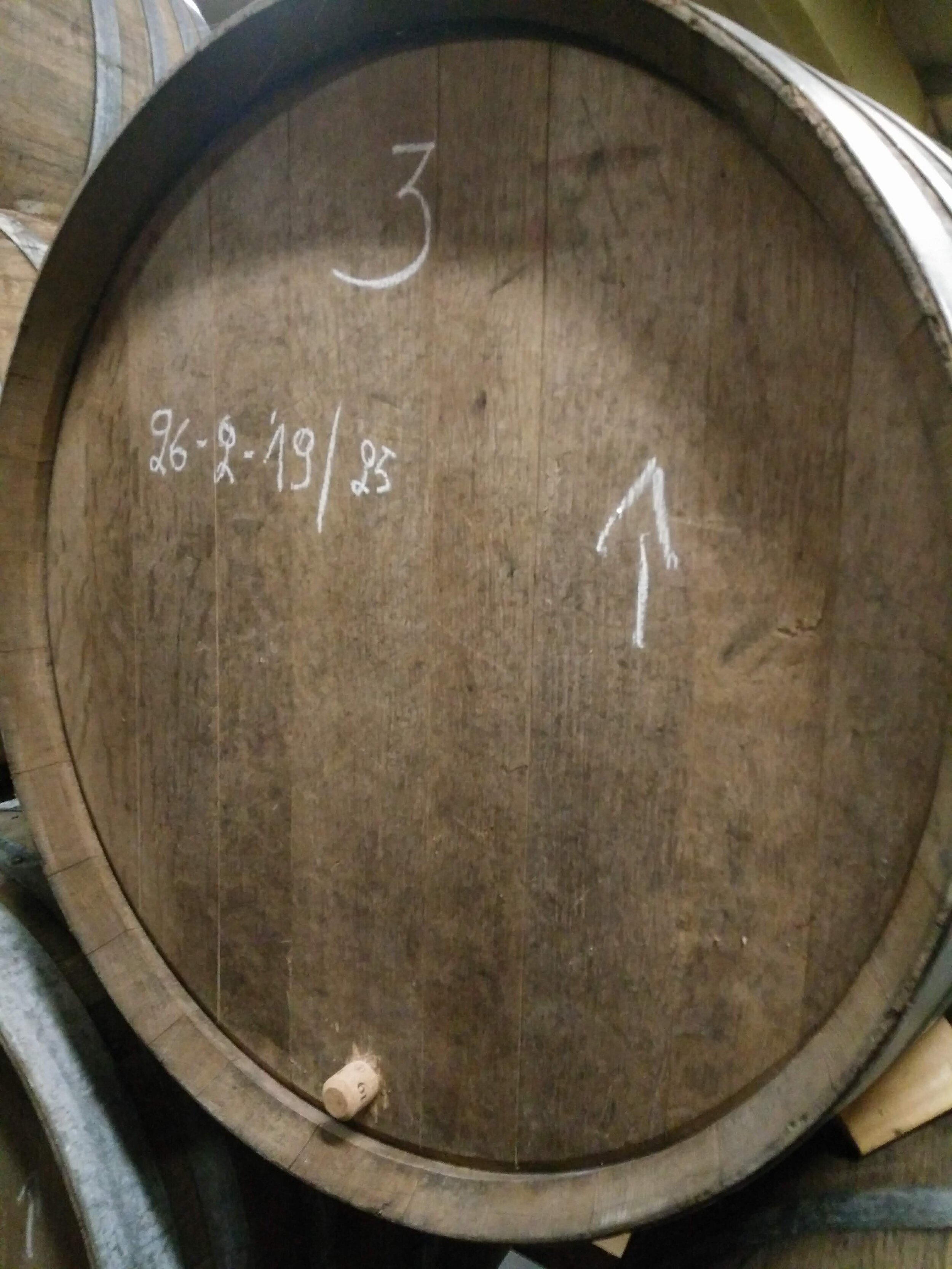

We were standing in their barrel room, kept at a constant 16 °C (acetobacter starts to reproduce at 22 °C) and 70% humidity. The first thing I noticed were the enigmatic signs written with chalk on the front of the barrels. Senne explained that some of the beer is brewed at the 3F brewery nearby in the town of Beersel and some are brewed at other breweries. The 3F-brewed barrels are marked with a 3, while the others are marked with a different symbol, such as the four squares with x’s, which signifies Lindeman’s. If you receive a green bottle of 3F, it is a blend of beers from multiple breweries. If it’s a brown bottle, all the wort was brewed by 3F.

At the 3F brewery, they brew only between October and March (or May, weather dependent). They source 15 year old Challenger and Hallertau hops from a guy with a hook instead of a hand. No joke. They boil for four hours to diminish the old hop cheesy funk aroma. All the wort is spontaneously inoculated by local “mischkes” (microbes) while in a coolship. If they brew when it is too warm, the wort will be soured by undesirable bacteria like pediococcus and acetobacter. After time in the coolship, the beer is transported over to the barrel room in large plastic tubs where they will be transferred to barrels for fermentation and aging.

All the barrels are old red wine barrels made from French oak. They do not wish to impart a woody flavor. Rather, they need the micro-oxidation that wood allows. They fill the barrels and once initial fermentation has settled down, they top it up with more wort to keep the barrel full for aging. There will always be some evaporation (endearingly termed the “Angel’s part”), but if it evaporates too quickly, the pellicle will not cover the entire surface of the liquid, resulting in vinegar rather than lambic. This is why the temperature and humidity are specifically controlled.

The beer ferments and ages in the same barrel. As Senne put it, “the beer is always with its mother.” Let’s discuss that for a minute because it is profound. Historical homebrewing wisdom was to transfer your beer to a secondary vessel after two to four weeks of primary fermentation or risk soy sauce flavors from autolysis. We’ve all questioned it: “Is it worth transferring to secondary, risking oxidation or infection, if I won’t be aging for long term?” “If I am aging long term, how long can I keep it on the yeast cake?” Now, with kveik yeasts, we’ve taken a turn. People think their beer is finished after one or two days of fermentation. Maybe the final gravity has been achieved, but for many, it will taste better if left on its mother for awhile longer. At 3F, some of these beers are aging on their trub for three years! Leave it on the cake, people!

After the beer has fermented and aged, it’s blended. This is a process that I’m super interested in and, of course, forgot to ask questions about while there. Senne highlighted 3F’s traditional processes. They have been doing this for over a century. Their lab consists of one small cart with some basic measuring equipment. They don’t know precisely which mischkes are in their beer, and they don’t care to find out. I speculate that for blending they trust a gut instinct. I can picture the master blender walking around, tapping a few barrels, mixing, tasting, and maybe doing a few blend comparisons by measuring the weight of each addition before deciding how to blend. There is some element of a secret sauce. After all, 3F started as a blendery before they ever brewed. In its recent history, blending has been passed down from father (Gaston Debelder) to son (Armand Debelder) to apprentice (Michael Blancquaert). It’s a special skill to taste a blend now and discern if it will taste good in a year or five.

The tap with sight glass

To blend, they tap the 500L barrels with a sight glass so they can get the beer without the trub. The beer is transferred into a CO2-flushed plastic tub and blended to a 6000L batch. The blend is allowed to settle overnight before bottling. This allows the flavors to meld and any remaining sediment to fall out of solution. The barrels are then deep cleaned and reused until they fall apart or make vinegar.

For fruit beers, 3F uses only hand picked fruit to ensure peak ripeness. The fruit is sanitized by freezing. The few stainless steel tanks they have are used to age the fruit beers, as they are much easier to clean than the barrels and foeders. For their Hommage beer, they first add cherries, and then raspberries. The cherries fall to the bottom of the tank and create a sieve that filters out the pesky, disintegrated raspberries.

20 year expiration date thanks to their quality corks. Drink the fruit beers young but hold on to the rest.

Senne started his career at 3F on the bottling line. All the bottles are labeled and corked in a small separate room using a champagne-corking machine, using the best corks around. The corks are good for up to 20 years and the bottles do not need to be stored on their side to prevent the cork from drying out and shrinking. All bottles are aged for at least six months in a room that’s around 20 °C. If they taste good after six months, they are sold. Otherwise they are aged longer and periodically tasted. Occasionally, a bad batch is identified. Whether it’s discovered at bottling or before, 3F simply discards it or continues aging the batch to see if it improves. They will not sell it. They have very high standards for the beer they produce and release. They brew and blend it with respect, so we must pour and taste it with respect. A lambic is a living beer, there will be sediment in the bottle. Use a lambic basket or find another way to pour the bottle in one smooth motion to prevent kicking up the sediment. I repeat: do not stir up the sediment. You want to taste the beer, not the yeast.

As we were leaving the room, a woman pointed to a box full of clear liquor bottles labeled “Armand’s Spirit”, and asked, “What are those?” Senne responded, “I wasn’t going to talk about this, but since you asked … “ He went on to tell us the story of the 2009 thermostat incident. Basically, there was an issue with the thermostat, which caused the bottle room to overheat to as high as 60 °C. This caused many of the bottles to explode and killed off the others. They lost an entire year’s worth of product. Some of the bottles were distilled into Armand’s Spirit, and, thankfully, the brewing community rallied around Armand. Lindeman’s and other breweries provided beer, saying to pay them back whenever it was possible. We see this kind of love and support a lot in the NYC homebrewing and professional brewing scene. I’m grateful that it’s not localized to just here. At one point there were over 300 lambic breweries, now there are only ten. Not only is 3F still here, but they are expanding. They will be constructing a larger space and will be implementing innovative things like QR codes on bottles so you can see all the information about a beer from the farm the wheat was grown on to the local weather when it was put in the coolship.

Pouring beer like a boss (sorry it’s so blurry … I was still taking notes!)

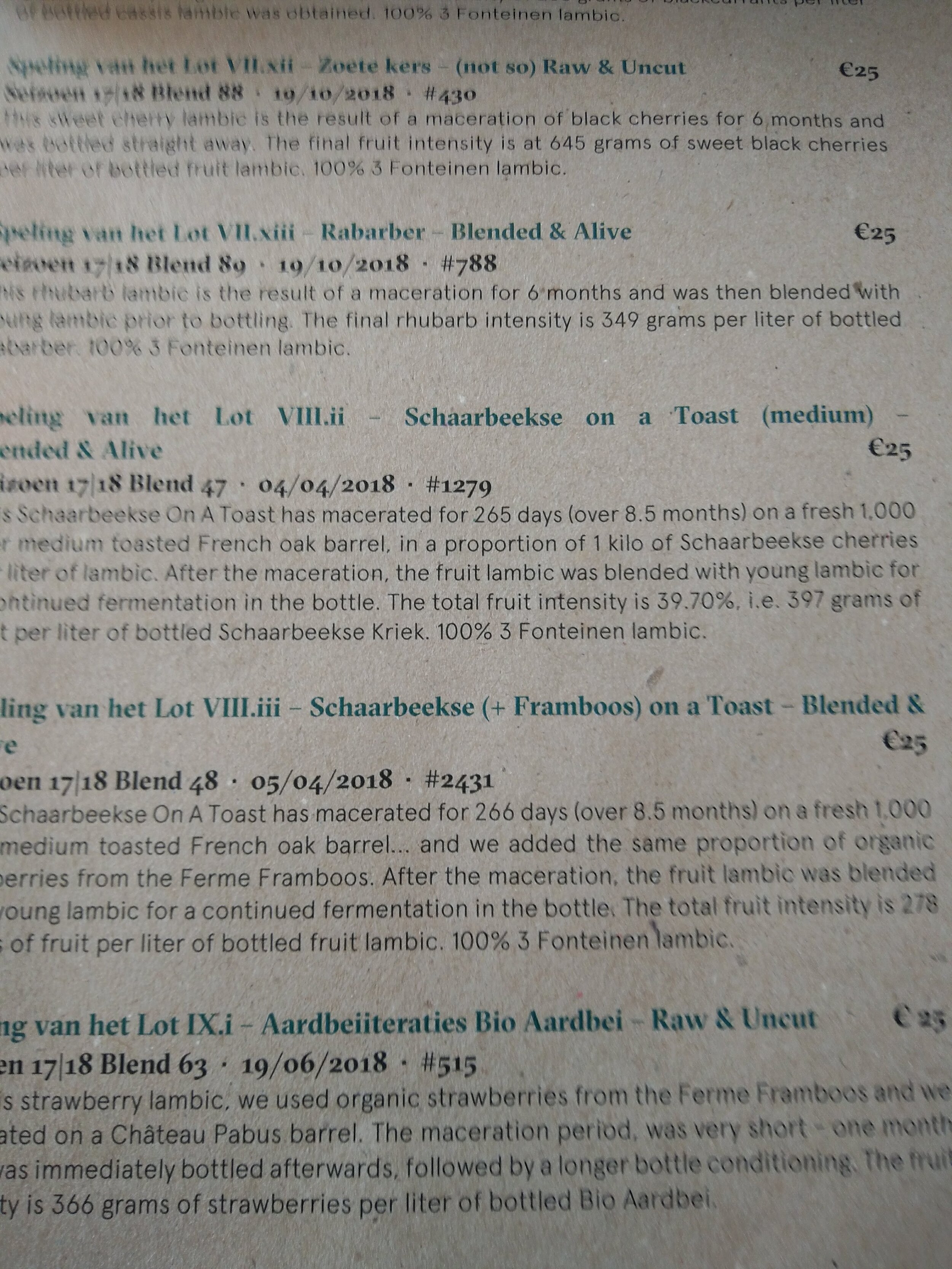

At the end of the tour, Senne expertly poured us a magnum of geuze and we headed into the tap room. They have two beers on tap: the young lambic and the farro (€3 each). I got the farro and sat down to explore their extensive bottle menu while chatting with the Brits. Unfortunately, the Brits left shortly after so I was on my own for tasting. The bottle menu had some amazing sounding beers on it, but most were only available to drink onsite. As I was there alone, there was only so much I could drink. Most were €25 750 mL bottles. I got a 375 mL bottle of the Oude Gueze Cuvee Gaston and Armand with Honey. It was spectacular. Smooth, floral, a little nutty from the honey, well balanced from age. I stopped at the bottle shop on my way out and purchased one of everything: several bottles of the Oude Gueze with and without honey as well as the Hommage. They do serve some food in the tap room, but I went to a chip shop up the street before heading back to Brussels for a visit to Cantillon.

Drie Fonteinen is well worth a visit during your trip to Brussels. They produce high quality, gobsmackingly delicious beers with a lot of history, knowledge, and passion behind them.

Tips for your beer visit to Belgium and 3F:

Download the SNCB app for train tickets, routes, and schedules

Stay near Brussels Central or Midi/Zuid. Cantillon is very close to Midi/Zuid, but it’s a bit further from the Old Town

Visit the tap room with at least one other person (or go in a chatty mood and share some bottles with a stranger :) as most bottles are 750 mL and are only available for onsite consumption

Check hours carefully as many of the breweries close early or are closed to the public on odd days,

Rent a bike! Particularly in the western part of the country, there are plenty well-demarcated bike paths, many of them between various breweries. Riding around the Westhoek during peak hop season is amazing. Be responsible and find a way to carry bottles back with you.