Decoction Experiment Results

In this experiment the Brewminaries tested methods of mashing against grain bills to create a Bohemian Pilsner. Many brewers have opted for using melanoidin malts in place of decoction since it can be time consuming and labor intensive. However, there is still debate about the capacity of the melanoidin malt to mimic the results of a decoction. In order to determine the effect of melanoidin on beer, and if this approaches can have similar results to decoction mashing, three brewers brewed a Bohemian Pilsner under the following conditions:

- Step mash by decoction

- Step mash by adding water and melanoidin malt

- Step mash by adding water without melanoidin malt

We had three judges perform a triangle test to ensure that they beers were distinctive, then rate the beers on a limited rating sheet based on the BJCP beer judging sheets. 24 Brewminaries also rated the beers on the same sheets. Without a doubt, the beers were distinctive in flavor. The judges had no issue picking which beer used which process, and the members’ feedback mimicked those results. The following results we enlightening and informative in which method makes great beer.

We hope the following results give you some insight into which process you can use to achieve the beer that you want.

The members and judges rated the beers similarly on overall mouthfeel.

Members

Judges

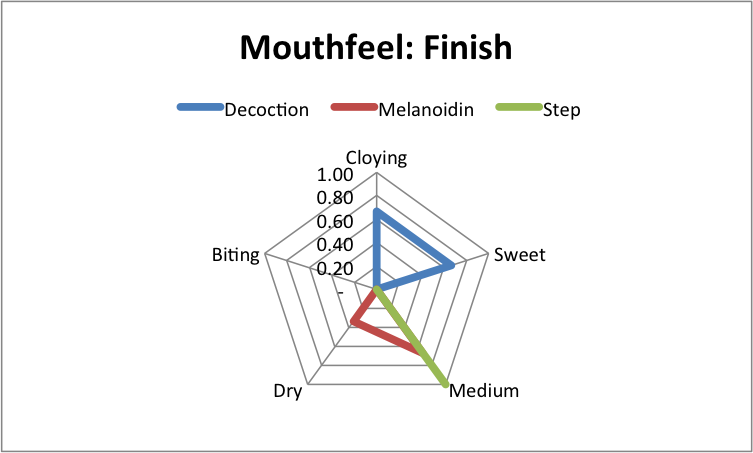

The group also judged the finish in a similar way, with the decoction condition ranking higher in sweetness and cloying.

Members

Judges

The members and judges rated the beers similarly on overall flavor. The members did rate higher in phenols and alcohol, where as the judges had more significant differences in malt and hop character between the beers.

Members

Judges

With malt flavor the group rated the step mashing and the melinoidin conditions nearly the same, but the judges ranked decoction higher in richness, which was not surprising considering their higher ratings in sweetness in the mouthfeel.

Members

Judges

The group also agreed on the hop flavor. The melenoidin condition had some herbal and earthy flavors, with medium citrus, which matches the overall flavor for hops and esters. The step mash condition had some earthy, floral and grassy hop flavor, with grassy flavor being more prominent with the members.

Members

Judges

The judges noted berry and grape flavors in the step condition, where the members did not in the ester profile. The decoction and melanodin conditions had similar ratings noting fruity, apple/pear, and citrus flavors.

Members

Judges

The balance was also very similar. The judges agreed that the melanoidin and step mash conditions where balance, where the decoction was the most malty. The members also thought the beers were mostly balanced, with decoction being maltier. Both groups also thought the melanoidin condition was slightly hoppy as indicated in the flavor ratings.

Members

Judges

The overall ranking was the most surprising. The judges preferred the cleaner, easy-drinking step mash condition. While they could distinguish which method was used in each beer, they enjoyed what was arguably the simplest process overall. The members enjoyed the melanoidin condition the most, with the other two coming in close for second.

he members had a great sense for what was happening in these beers. The step mash condition was ranked grainier, while the melanoidin and decoction conditions were ranked maltier, breadier and having more caramel. This is what we expected from these brews! Overall, it looks like you can comfortably brew with melanoidin malts to mimic decoction flavors.

Notes on the beers:

- The decoction was a triple decoction through the same temperature steps as the other conditions.

- The melanoidin condition had a diacetyl rest with temperatures that reached the mid 70’s degrees Fahrenheit.

- Decoction FG: 1.012, Melanoid FG: 1.011, Step FG: 1.012

Fermentation Schedule

- Primary Fermentation: 50°F for 14 days

- Diacetyl Rest: 65°F for 4 days

- Cold Crash: 35°F for 3 days

- Transfer to keg

- Lager: 38°F for 28 days

- Force Carbonate: 38°F for 3 days